Painted aluminium for windows, doors and shading systems

Whether shading systems such as roller shutters and external blinds or window frames – aluminium impresses with its high load-bearing capacity, durability, weather resistance and energy efficiency. Do not make any compromises when choosing the material. As experts in the production of bare and painted aluminium as a primary material for windows, panelling, roller shutters and doors, we have the highest level of expertise, experience, and the most technologically advanced manufacturing processes.

Use of aluminium for windows and shading systems in the modern architecture and construction industry

Modern designs and complex architecture characterize the urban cityscape today. Façade cladding made of aluminium reflects an innovative building culture in a variety of ways and sets the highest standards in terms of both overall appearance and functionality. Window cladding and shading systems made from this impressively versatile material are in no way inferior to this approach.

A major advantage of window frames made of aluminium: The scope for individual design knows almost no limits. Paintwork can be matched to personal wishes and circumstances and offers a wide range of design options – from corporate design to purist straightforwardness.

When it comes to maximum durability

An aluminium window frame as well as roller shutters and external venetian blinds not only give buildings that decisive finishing touch in terms of appearance. Alloys and paintwork also ensure a resilience that goes beyond all measure. Pre-painted hinges for windows from Speira can withstand extreme weather conditions with ease and have maximum elasticity. Our in-depth expertise in the field of coatings and in the architecture and construction segment is the foundation for long-life, durable aluminium windows.

Uncompromising energy efficiency

Likewise, window frames of aluminium and aluminium solar shading systems meet today's energy efficiency requirements. The material in combination with PU foam, for example, serves as highly effective heat storage and insulation. Roller shutters and external blinds can be used to regulate lighting conditions and the indoor climate in every season. Hardly any heat is lost with aluminium window frames. With these properties, aluminium is the right choice when it comes to your own requirements as well as the regulatory requirements of environmental compliance.

Get in touch Discuss your next project with us

Our team is always ready to listen to you. Feel free to contact us with all your questions and requirements in the area of shading systems and window frames - and let us shape the future together as partners.

You can reach our experts via the contact form. We look forward to hearing from you.

Aluminium for windows

While PVC-U dominated the market just a few years ago, the focus is now shifting towards robust solutions due to the awareness of quality, durability, and energy saving. Energy efficient aluminium windows or wooden windows with a high-quality lacquered aluminium shell have the ideal properties for this and are superior to PVC-U variants in many respects.

The combination of wood and aluminium is particularly effective for roof windows. The robust timber profile is encased in an attached aluminium shell, which protects it from all weather conditions, increases thermal insulation and embodies a modern design. Window frames of aluminium are the first choice for roof windows, as the loads are particularly high here.

- High-quality coatings for semi-finished aluminium products for windows and doors with weather and UV-resistant surfaces

- Maximum energy efficiency thanks to high-performance thermal insulation

- Particularly long service life

- Unlimited design options from large window elements to narrow window frames made of aluminium

- Full access to the entire RAL color palette

- High flexibility in terms of shape

- Easy to clean and low maintenance

- Fully recyclable

Aluminium for shading systems

Today, shading systems not only have the task of protecting rooms from direct sunlight. The demands on energy efficiency, privacy, noise protection and appearance are equally high. Modern roller shutters and external venetian blinds made of painted aluminium meet these requirements – for many years and generations to come. The material is just as resistant to rust and weathering as it is to UV radiation or extreme weather conditions.

Individual regulation, especially for external venetian blinds with slats, allows the light and room conditions inside to be optimally controlled. In this way, aluminium serves as sun protection, increases the overall efficiency of the building, and ensures an adjustable incidence of light.

As with window frames made of aluminium, shading systems can also be individually tailored to customer requirements to act as a modern style element on building façades.

Our flat rolled aluminium for windows is suitable to produce front-mounted roller shutters and top-mounted roller shutters as well as façade venetian blinds and front-mounted venetian blinds.

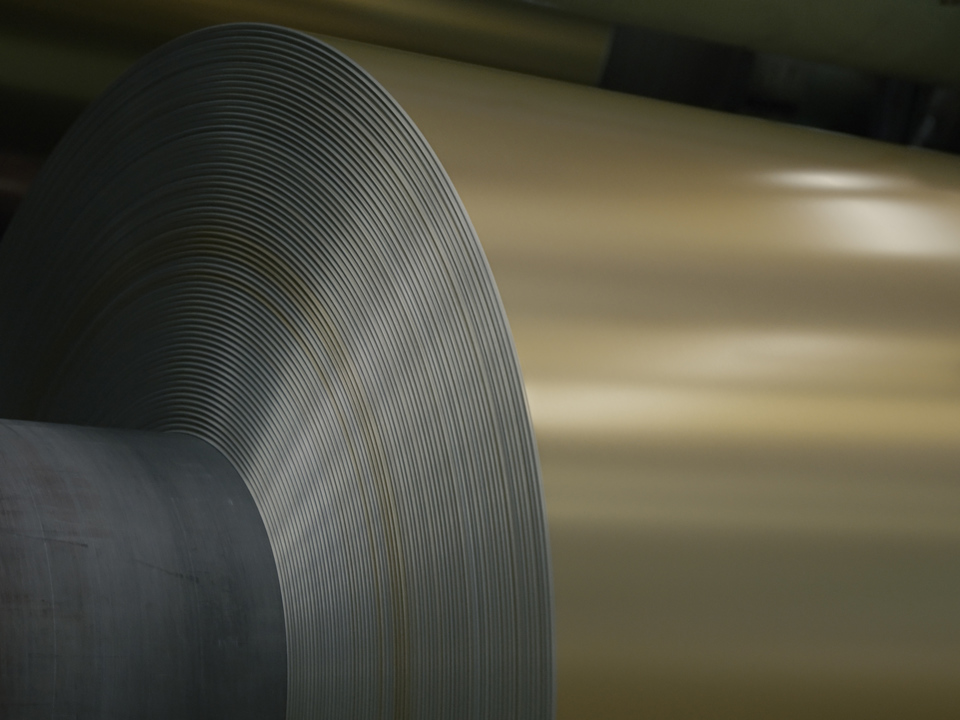

Over 30 years of experience in coil coating of aluminium for window frames and shading

At Speira, we use the coil coating process to produce aluminium for window frames and shading systems. Coil coating in a production line ensures that we can produce the material exactly as you imagine it. During the process, the aluminium coils are cleaned, pre-treated, painted, and hardened. The cleaning and preparation serve as the basis for uncompromising adhesion of the lacquers, which we apply using state-of-the-art rollers. After drying and hardening in the oven, the now coated aluminium is rolled up in the form of a strip, then cut to the required final width and then finds its way to your production facility.

What makes the difference for us? We have over 30 years of experience in alloying and painting. Renowned customers from a wide range of industries have trusted our specialists from the very beginning. We know exactly which requirements need to be met in which areas to produce a coating that can withstand the stresses and strains. At the same time, you benefit from our awareness of aesthetics, which enables us to provide you with all-round expert advice in every respect.

Sustainability and energy efficiency of aluminium for windows and doors

Another advantage of shading systems and window frames made of aluminium is their high recyclability. We place great importance on recycling-friendly alloys that can be recycled indefinitely. A quality feature that makes a significant contribution to sustainability.

In terms of energy efficiency, windows and window frames made from a timber-aluminium construction often focus on excellent insulation quality. What is often overlooked is the control and regulation of light incidence using external blinds. The individual slats allow the amount of light to be adapted to the use inside. Shading with aluminium makes the indoor climate much more pleasant. The heat output is reduced due to the incidence of the sun's rays as a heat source. Cold can be effectively kept out by closed roller shutters.

We are your partner when it comes to painted shading and window frames made of aluminium

Robust, resistant, adaptable: Aluminium is a material that is already playing an important role in many areas today and will continue to do so in the future – far beyond the well-known aluminium packaging and the use of aluminium in vehicle construction.

Whether you need window frames of aluminium or high-quality shading systems, we at Speira supply you with a primary material that meets the highest demands. Benefit from our high level of expertise when it comes to alloys and coatings and rely on over 30 years of experience.

Let our experts provide you with comprehensive advice. Together we will find individual aluminium solutions for your construction project. Simply contact us without obligation using the form below.

Contact us

FAQ: Aluminium Window Frames and Doors

For extruded aluminium window and door frames, fabricators primarily rely on the 6xxx family, particularly EN AW-6060 and 6063. These alloys offer the right balance of strength, excellent extrudability, clean surface quality, and tight dimensional tolerances, making them ideal for slim, load-bearing frames with large glass panels. When it comes to slats, roller shutter profiles, cover shells, and formed strips, 3xxx and 5xxx alloys are the preferred choice. They offer outstanding formability, high corrosion resistance, and reliable paint adhesion during coil coating. Speira supplies these alloys as a bare or pre-coated strip, precisely matched to your production needs – from edge stability and forming tolerance to flat winding for smooth downstream processing.

Aluminium is classified as a non-combustible building material. In Germany, it falls under DIN 4102-1 (A1), while European classification follows DIN EN 13501-1 (typically A1, though some products may be A1/A2 depending on construction). It’s important to distinguish between solid aluminium components and composite materials with a plastic core, as the fire behavior is determined by the composite structure. Pure aluminium frames behave differently from bonded panel systems. For any given project, it is thus the specific construction and installation approach that determine the fire classification. At Speira, we supply pre-material grades suitable for demanding fire protection requirements.

Aluminium is a highly durable and resilient material. When combined with high-quality alloys, corrosion-resistant pretreatment, and pre-coated strip, aluminium roller shutters and windows retain both their function and appearance for decades. They stand up to hail, strong winds, and intense UV exposure without cracking, chipping, or showing significant signs of aging. Maintenance is minimal. Usually, an occasional wash with water and a mild detergent is all that’s needed. The coil-coated surfaces are also abrasion- and UV-resistant, keeping their gloss and providing lasting protection against corrosion.

Coated aluminium offers the complete RAL color range, from minimalist gray tones like anthracite to bold corporate colors. Whether you’re aiming for a matte, satin, glossy, or finely textured finish, the desired look can be precisely achieved, color-matched with long-term stability, and reliably reproduced over time. Speira’s coil coating creates uniform, durable layers on the coil that flex with the material during forming and profiling while preserving the finish’s appearance over the long term.

While aluminium has a higher upfront cost than plastic, it often proves more economical over the long term. Its extended service life, minimal need for repairs, and consistently high-quality appearance help reduce follow-up expenses throughout the product’s lifecycle. Retrofitting is straightforward as well, whether you’re upgrading an older building, replacing damaged plastic components after storm or hail events, or modernizing an existing installation.

In addition, aluminium window frames and shading systems can enhance a property’s value. Their wide range of colors allows them to blend seamlessly with contemporary architecture, increasing the visual appeal for both buyers and tenants.

Our coils are used in surface-mounted and built-on roller shutters, façade and surface-mounted exterior blinds, cover shells for wood-aluminium windows, and various other architectural profiles. We engineer the material properties to ensure that forming, punching, and profiling processes run reliably while the surface maintains its character over the long term. The result is a pre-material that performs consistently in production, delivers a clean, high-quality appearance on the building, and returns to the recycling loop at the end of its lifecycle without loss of quality.

Yes, this is exactly where aluminium shines. Its high flexural rigidity maintains shape integrity even at widths beyond 1.5 to 2 meters, allowing roller shutters to operate smoothly while frames stay slim. Windows made with aluminium deliver delicate sightlines, maximized glass area, and architecture that excels both functionally and visually, even in wind-exposed locations or with wood-aluminium skylight assemblies. Unlike plastic alternatives, aluminium frames are far less prone to warping or gapping. For maximum darkness, selecting the right profile size, precisely matched guide rails, and proper end-position adjustment is key. This ensures reliably dark rooms, even with large-format installations.