Battery systems Powering into the future

Reliability from battery cell to chassis – our tailor-made material solutions are advancing electric mobility

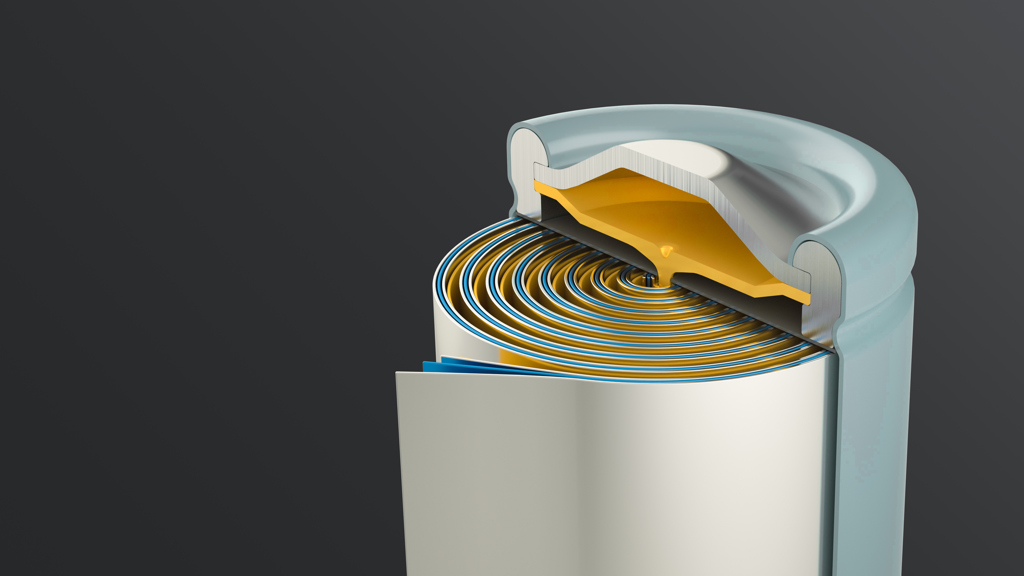

At Speira, we have long recognized this trend and made an early start on developing customized aluminium alloys that push battery technology forward. Today, we are a volume supplier to leading global battery manufacturers and offer an extensive product portfolio that covers the entire spectrum from battery electrode foils to cell connectors, heat exchangers, and housing materials.

It is exactly this broad view of the market and technology, coupled with our many years of experience, that make us a reliable development partner. Together with you, we strive to shape the future of electric mobility and battery technology by working together to make individual product solutions a success.

Our Speira ION for your battery system: From mobility and energy supplies to power tools – the future is electric. And modern battery technology demands high-performance materials.

Reliable connection – efficient conductivity Our material solutions for busbars and contact systems

Keep the power on with our aluminium solutions for contact systems and busbars. Our materials enable a skillful balance between high specific conductivity, lightweight potential, and minimal contact resistance. And we don't need to shy away from comparisons with copper materials here: Fast-growing markets demand reliable performance on a top level, with low costs at the same time - here, our aluminium clearly has the edge. Contact us and we'll find the ideal solution for your efficient battery system.

Always at a comfortable temperature Thermal management with Speira aluminium for greater driving range and longer service life

Modern battery systems show optimal performance and service life between approx. 20°C and 40°C. The task of thermal management systems is to ensure this "sweet spot" and to keep the battery at a comfortable operating temperature. Our specially developed materials for heat exchangers in battery applications guarantee sophisticated and efficient thermal management, whether it's during fast charging or out on the road. Thanks to their excellent malleability, adhesive and soldering properties, and ease of further processing, our materials enable tailor-made solutions for every application.

Our strongest material for your safety We combine crash safety and vehicle performance with robust material solutions

The vehicles of the future are powerful, safe, and efficient. We are paving the way for this with our tailored aluminium alloys for battery casings, combining maximum robustness with the potential for economical lightweight design. Our materials not only protect your battery in the event of a crash - corrosion is also efficiently avoided and the high thermal conductivity of aluminium enables improved thermal management under both hot and cold conditions. In addition, battery casing made of our materials meet all requirements for electromagnetic compatibility (EMC) as well as water and gas sealing.

Do you need complex geometries and precisely-fitting solutions, too? No problem, because our versatile alloys for battery casings are also weldable and can be reformed optimally.